Expertly managed field operations

Bridge Energies, an independent French company, was set up in 2006 to carry out hydrocarbons exploration and production in the Paris Basin. Its head offices are at Châtellerault (Vienne department, France). Bridge Energies has just one mining title: the Nonville lease.

Oil production by Bridge Energies accounted for 0.47% of national production and 0.78% of Paris Basin production in 2021.

To support its development, Bridge Energies is conducting extensive geoscience studies with in-depth geological studies, reservoir studies and geophysical studies (acquisition of 318 km of geophysical lines, data reprocessing, interpretation, new structural maps).

A lease at the heart of the Paris Basin

Bridge Energies was set up in 2006 to carry out hydrocarbon exploration and production in the Paris Basin

Its head offices are at Châtellerault (Vienne department, France). Bridge Energies has just one mining title:

the Nonville lease.

Local oil in safe hands, the effective

alternative to importing

Oil was first discovered in the Paris Basin in the 1950s. For decades, the skills and techniques for tapping into the resources beneath French soil have been evolving, and in ways that respect the environment. Bridge Energies is working within the legacy of this know-how. Our activity has a full role to play in France’s energy mix, as it has an extremely low carbon footprint compared with that of imported oil. Crude oil produced in France actually emits three times less CO2 than imported crude. At present, oil produced in France each year represents 1% of the country’s consumption; in-country production avoids nearly 100,000 tonnes of CO2 emissions a year compared to imported oil.

History of

the Nonville reservoir

The Nonville reservoir was discovered at the end of the 1950s, under the “Villemer” lease name. The Autonomous Petroleum Administration (RAP) would drill 17 wells between 1959 and 1962 (VM101 to VM121), and then the ERAP (Enterprise for Petroleum Research and Activity – ELF) drilled wells VM122 and VM123 in 1967 and 1972 respectively. Subsequently, Elf Aquitaine drilled wells VM124 and VM125 in 1978, and VM126 in 1988, which was to be the last. Elf decided to close the reservoir in 1994, though the resources were not depleted; the economic conditions at the time favoured the development of larger fields overseas.

Production restricted to 10 km²

in Seine-et-Marne

The lease known as Nonville is located in France’s Seine-et-Marne department. It has a surface area of 10 km², and extends mainly across the Nonville district but also includes parts of the Darvault, Genevraye and Villemer districts.

Production restricted to 10 km²

in Seine-et-Marne

The lease known as Nonville is located in France’s Seine-et-Marne department. It has a surface area of 10 km², and extends mainly across the Nonville district but also includes parts of the Darvault, Genevraye and Villemer districts.

Carefully considered drilling techniques

that work with the environment

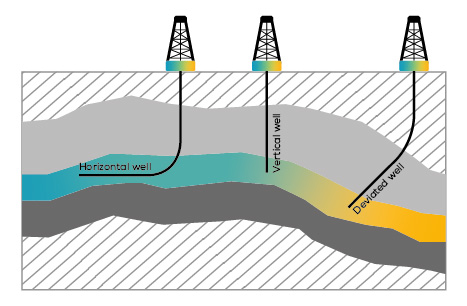

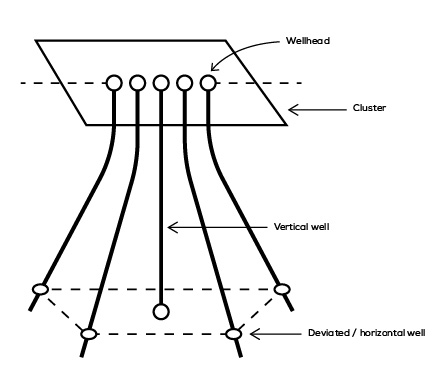

The different well types: Wells may be drilled vertically, horizontally or deviated. These directional drilling techniques help minimise the environmental impact at the surface, and also the economic impact.

The platform currently in place at Nonville has one producing well, the horizontal well NVL2H.

Our technologies

To produce oil, “producer” completion equipment is run into the wells to bring the fluid up to the surface.

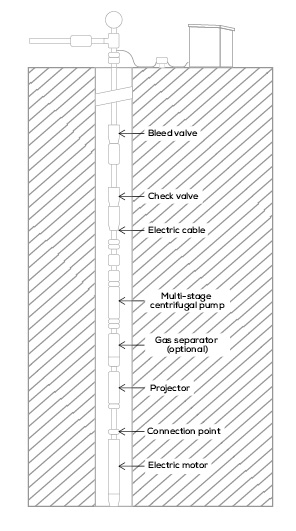

The well currently in production uses an ESP (electric submersible pump), a GE technology.

Other pumping systems exist but are not used on the Nonville site.

Electric submersible pump technology

Well NVL2H is equipped with centrifugal pumping and has an electric submersible pump (ESP). The centrifugal pump is lowered on its side into the casing, suspended on the end of the production tubing. Electrical energy is sent to the motor via a cable that is unwound as the tubing is lowered, and attached to the tubing with clamps. The diagram shows the components of this system. A centrifugal pump may comprise hundreds of stages. Installing this kind of facility enables production from highly deviated wells that may have high flow rates (in excess of 1000 m3/day). All that remains on the surface is the wellhead and an electrical transformer station, which may be located remotely. This type of pumping blends into the landscape very well.

Our preventive

maintenance

It is necessary to carry out work on oil wells for preventive maintenance or repair any equipment breakdown. When this takes place, a pulling rig or workover rig and its personnel are brought in to perform the maintenance. These rigs are small and suited to the purposes of this work.

Our careful management

of reservoir water

The effluent (a mixture of oil and water) extracted from the wells goes into a three-phase separator.

Due simply to the difference in their densities, the oil and water separate from each other.

The oil is sent to a storage tank before being shipped to a refinery in a tank truck.

The water is sent into a buffer tank, and subsequently injected back into the reservoir it came from by means of an injection well (NVL101).

Our site restoration method

and compliance

As regards closure of a site or well, Bridge Energies has made commitments and planned the necessary actions depending on the site’s development (number of wells, surface area). The end of production comprises two stages: ceasing works and then restoring the site.

Therefore, the first stage is to shut down and plug the well(s). For this purpose, Bridge Energies submits a well plugging programme to the prefecture before the start of works. During the plugging operations, various measures are taken to ensure that the well is 100% sealed.

Bridge Energies will then issue a statement declaring the permanent cessation of works and of mining facility use (DADT in French), and this will be sent to the Prefecture at least 6 months before the end of oil production. Therefore, the site restitution programme is submitted to the Prefecture for approval before this work begins. Upstream, a full environmental diagnosis will be run to evaluate the condition of the site environment; this will enable clean-up work to begin, if necessary.

The DADT notice is accompanied by a Prefectoral order authorising restoration work. When this work has finished, will send the Prefecture a work completion report with all the necessary supporting documents and a statement of restoration conformity from the landowner(s).

Once this work completion file has been examined by the Prefecture, the latter can issue a Prefectoral order lifting the mining regulations, which stipulates that the operator has entirely fulfilled its site restoration obligations. Only at this point will Bridge Energies be released from its responsibility, which then passes to the French State.

The State, which is responsible for post-mining activities, takes great care to ensure that mining operators uphold their site abandonment commitments.